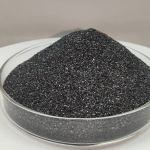

Black silicon carbide for skateboard sandpaper

Why Black Silicon Carbide is the Ideal Grit for Skateboarding The primary function of grip tape is to provide an extremely high level of friction between the skateboarder’s shoes and the deck, allowing for precise control during tricks like ollies, flips, and shuvits. Black Silicon Carbide (SiC) is perfectly suited for this task due to