What size of black silicon carbide is used for bolt grinding?

What size of black silicon carbide is used for bolt grinding?

Home » News

What size of black silicon carbide is used for bolt grinding?

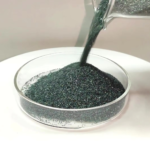

Black silicon carbide for bolt grinding and polishing Key Properties & Advantages Exceptional Hardness (9.5 Mohs): Second only to diamond and boron carbide High Thermal Conductivity: Dissipates heat effectively during grinding Sharp, Brittle Fracture: Creates fresh cutting edges continuously Chemical Stability: Resists reactions with most metals Cost-Effective: More economical than diamond or CBN abrasives Primary Applications

1. The Role of Green Silicon Carbide Green SiC is harder and more brittle than black SiC, producing sharper fractures. This makes it ideal for stock removal and shaping silicon before the final precision polish. It is used in free abrasive slurry form (loose grains mixed with a carrier fluid) in lapping processes. 2. Typical Grit Sizes Used The

Green silicon carbide 60# for sandblasting stainless steel strip Green silicon carbide 60# is an excellent choice for sandblasting stainless steel strip. This high-purity abrasive material offers superior performance characteristics that make it ideal for surface preparation and finishing applications on stainless steel. Key Properties Physical Characteristics: Hardness: Mohs hardness of 9.0-9.4, making it one

Applications of Green Silicon Carbide in Cemented Carbide Passivation Main Uses: 1. Sandblasting Passivation: Green silicon carbide abrasive (46 mesh, 120 mesh, 320 mesh, etc.) is used for sandblasting cemented carbide products, effectively removing burrs, oxide layers, and rough surfaces, improving surface finish. 2. Grinding and Polishing: Green silicon carbide micropowder (400# 600#800#, etc.) is

Green Silicon Carbide for Sandblasting Aluminum Alloy Panels Green silicon carbide (SiC) is a widely used abrasive material for sandblasting aluminum alloy panels, thanks to its high hardness, sharp edges, and good chemical stability. Below is a detailed analysis of its application characteristics, advantages, operating precautions, and alternatives. 1. Core Advantages of Green Silicon Carbide