Green Silicon Carbide VS Black Silicon Carbide

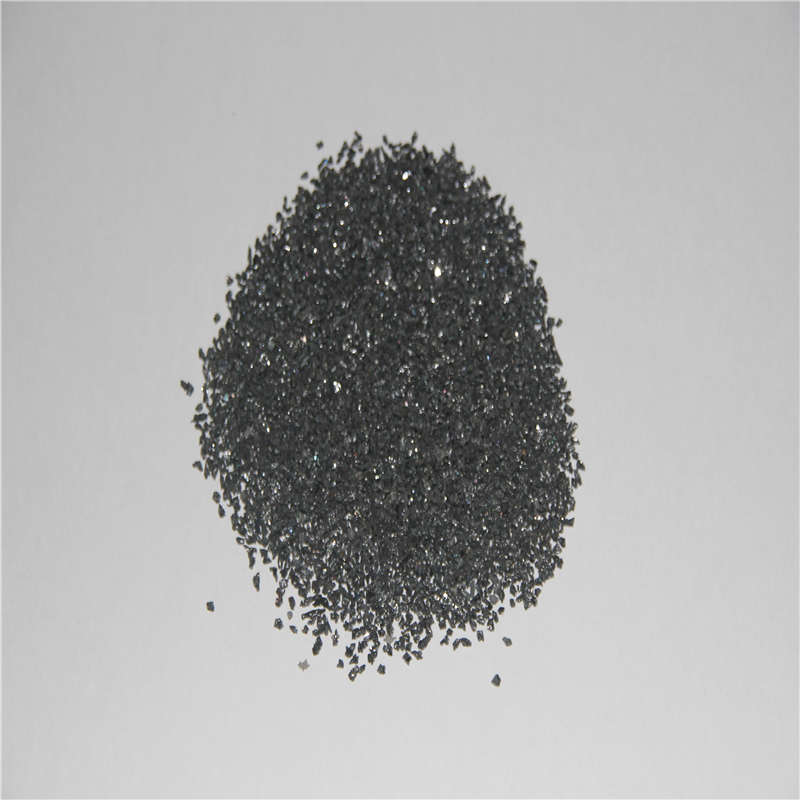

Silicon carbide has two commonly used basic varieties, black silicon carbide and green silicon carbide, both of which belong to α-SiC.

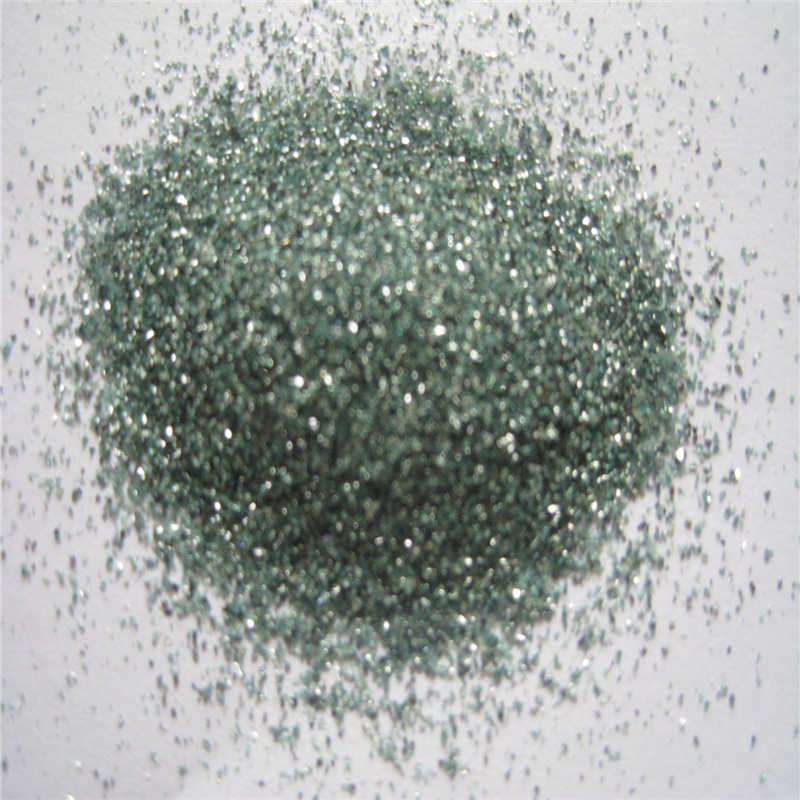

Green silicon carbide and black silicon carbide are basically the same, but the raw materials and manufacturing processes are different. The product is green and translucent, and its hardness and purity are better than black silicon carbide. Its elastic coefficient reaches 410GPa, and it will not dissolve under normal temperature and pressure. It will be consumed when the temperature reaches 1600°C or more, and it will decompose when it reaches 2815.5°C.

①Black silicon carbide contains about 98.5% SiC, and its toughness is higher than that of green silicon carbide. It is mostly used for processing materials with low tensile strength, such as glass, ceramics, stone, refractory materials, cast iron and non-ferrous metals.

②Green silicon carbide contains more than 99% SiC and has good self-sharpening properties. In addition, there is cubic silicon carbide, which is a yellow-green crystal made by a special process. The abrasive tool used to make it is suitable for super-finishing of bearings, and the surface roughness can be processed from Ra32~0.16 microns to Ra0.04~ 0.02 microns.

Green silicon carbide chemical coefficient: due to its stable chemical properties, high thermal conductivity, small thermal expansion coefficient, and good wear resistance, in addition to being used as abrasives, there are many other uses, such as: coating silicon carbide powder on turbine impellers by a special process Or the inner wall of the cylinder block, which can improve its wear resistance and prolong the service life by 1 to 2 times; the high-grade refractory material used to make it is resistant to shock, small in size, light in weight, high in strength, and good in energy saving effect. Low-grade silicon carbide (containing about 85% SiC) is an excellent deoxidizer. It can speed up steelmaking, control chemical composition and improve the quality of steel. In addition, silicon carbide is also widely used in the production of silicon carbon for electric heating elements. Great.

Green silicon carbide is suitable for grinding copper, brass, aluminum, precious stones, optical glass, ceramics and other hard alloys, metals and hard and brittle non-metallic materials. Its micropowder can also be used as a ceramic material. Due to the high purity of black silicon carbide, it is also widely used in the manufacture of refractory materials and various abrasive tools.

Uses: Widely used in grinding wheel, aviation field, sandblasting, coating, composite material, compound, kiln, polishing, polishing, sawing of refractory, silicon, quartz, etc.