What are the advantages of silicon carbide sandblasting abrasives?

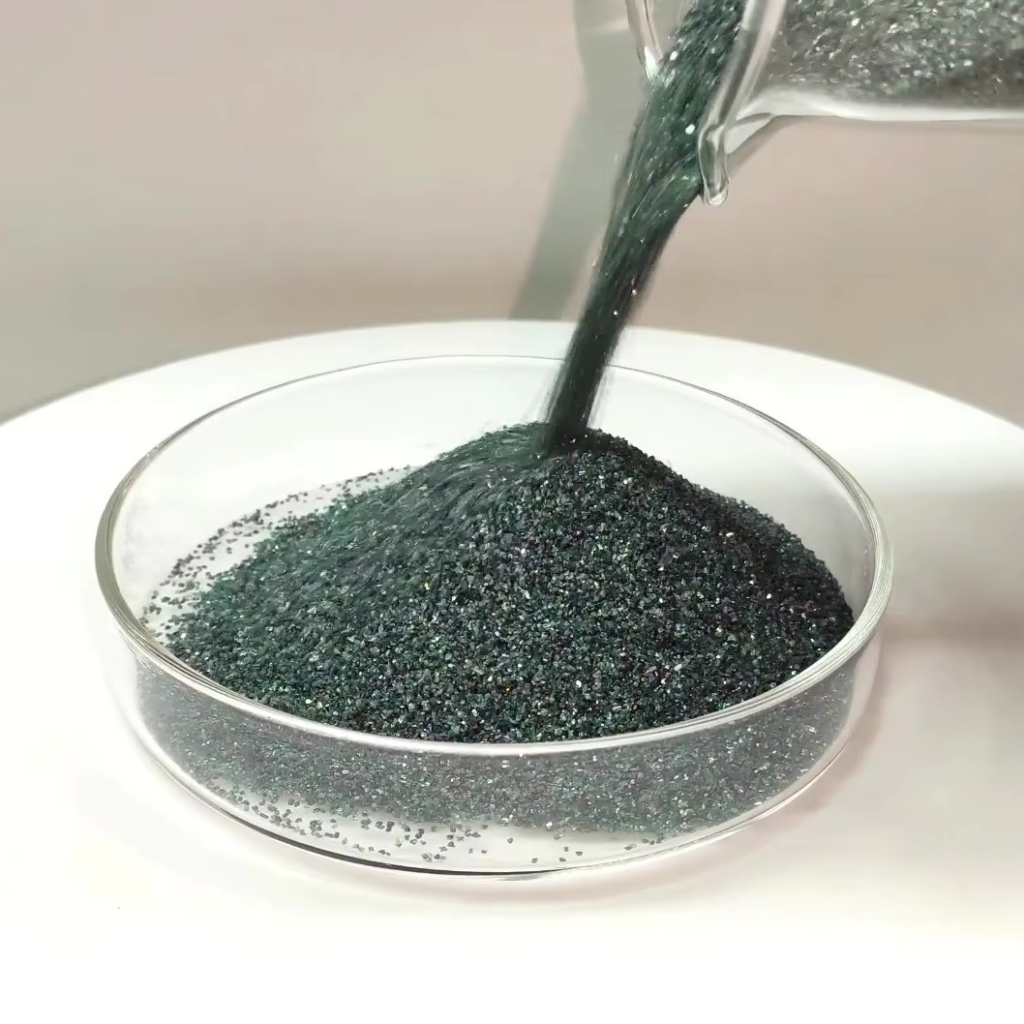

Silicon carbide is the hardest abrasive after diamond and boron carbide, but the price is only 1/10 of boron carbide, and silicon carbide comes in two colors, green silicon carbide and black silicon carbide

The hardness of green silicon carbide: Mohs hardness 9.3

Hardness of black silicon carbide: Mohs hardness 9.2

Silicon carbide has high hardness and most materials can be sandblasted and polished with silicon carbide.

Silicon carbide sandblasting can achieve the required cleanliness, surface roughness, and improve the adhesion of the coating.

After sandblasting with silicon carbide, the coating life of the workpiece is increased by more than 3.5 times. Another advantage of sandblasting is that the surface roughness is predetermined and easily achievable.