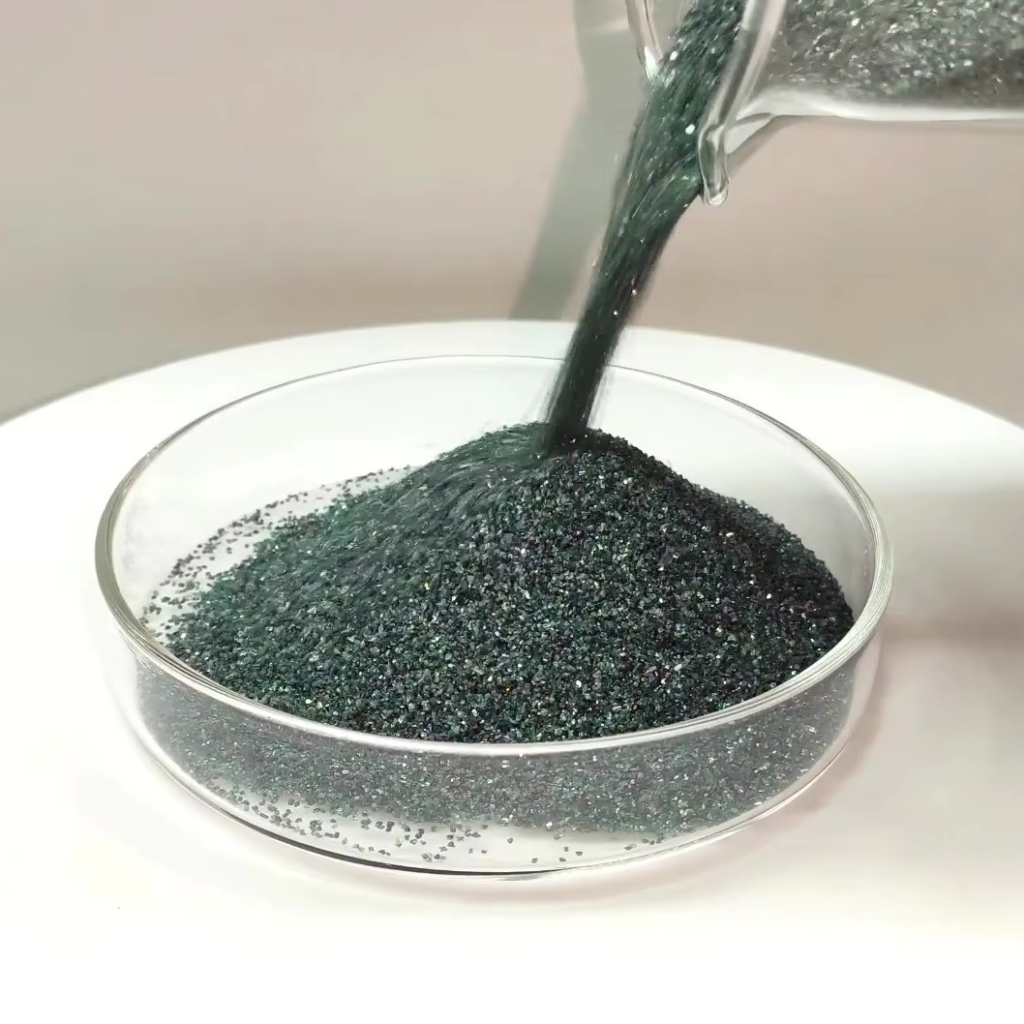

Quality control of green silicon carbide

Strictly control raw materials, semi-finished products, and finished products during the production process,

Testing methods: physical performance testing, and other methods,

The detected content ensures that key indicators such as purity, hardness, and particle size of the silicon carbid

In summary, the production process of green silicon carbide is a complex and refined process that requires strict control of parameters and conditions in each link to obtain high-quality products.

Raw material selection:

green silicon carbide raw materials :Petroleum coke, silica, and salts. Raw materials affect the purity of silicon carbide

Raw material processing:

Crush the selected raw materials to obtain particle sizes suitable for subsequent processing.

Acid washing raw materials can improve the purity of silicon carbide

green silicon carbide raw materials :Petroleum coke, silica, and salts. Raw materials affect the purity of silicon carbide

Raw material processing:

Crush the selected raw materials to obtain particle sizes suitable for subsequent processing.

Acid washing raw materials can improve the purity of silicon carbide