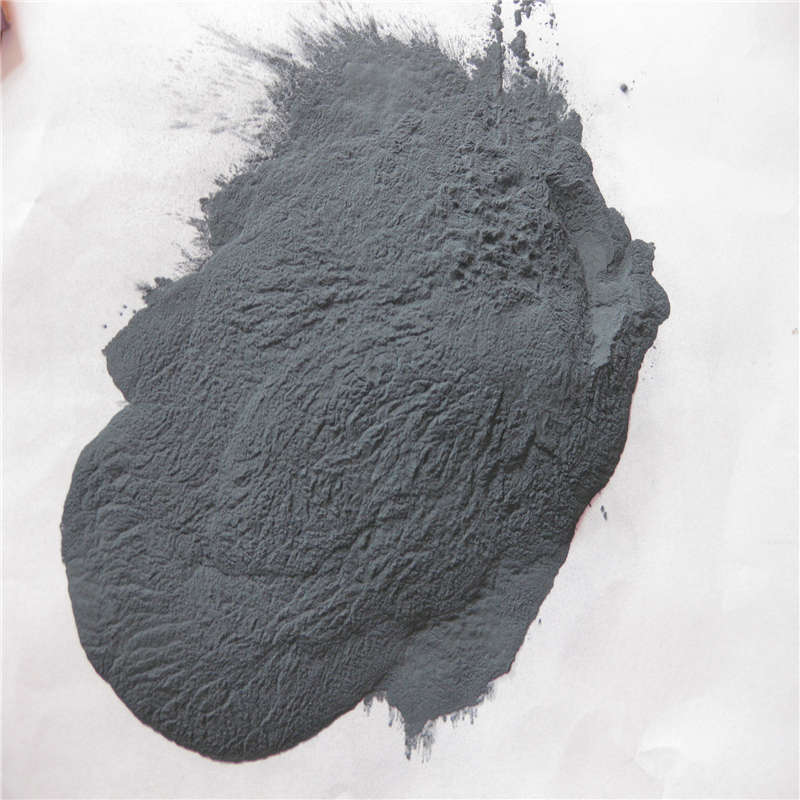

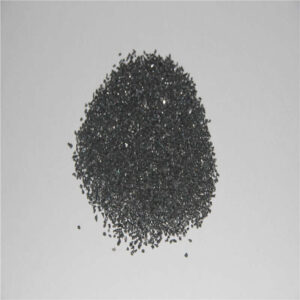

black silicon carbide emery sic P400

What is silicon carbide

Silicon carbide can also be called SiC. In terms of color, there are two kinds of black silicon carbide and green silicon carbide. According to the shape, there are silicon carbide grit and silicon carbide powder.

black silicon carbide emery sic P400

manufacturing process:

Silicon carbide is made of quartz sand, petroleum coke (or coal char), sawdust and other raw materials put it into an resitance furnace, heat it to a high temperature of about 2000 °C, and obtain silicon carbide after various chemical processes. To green silicon carbide, add salt.

black silicon carbide emery sic P400

specifications

component% | ||

SiC | F.C | Fe2O3 |

98.5 min | 0.2 max | 0.6 max |

black silicon carbide emery sic P400

properties

· Extremely high hardness

· Wear resistant

· Corrosion resistant

· Lightweight – Low Density

· High thermal conductivity

· Low thermal expansion coefficient

· Chemically and temperature resistant

· Outstanding thermal shock resistance

black silicon carbide emery sic P400

applications

What is silicon carbide used for? Silicon carbide has its own advantages and characteristics. So it is used in various industries.

· As an abrasive, it can be used as a grinding tool, such as grinding wheel, oil stone, grinding head, sand tile, etc.

· As a metallurgical deoxidizer and high temperature resistant material.

· High-purity single crystals can be used to make semiconductors and silicon carbide fibers.

· Can be used as a deoxidizer for steel making and a modifier for cast iron construction.