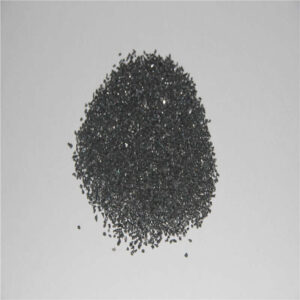

silicon carbide black use for abrasives and marble grinding and polishing media

Product introduction

silicon carbide for abrasives is made from quartz sand and petroleum coke(smokeless acetylene) as the main raw material.it is made via light resistance from hydrometallurgical,it is black opaque body hexagonal crystal and MOHS -hardness in the 9.3,which is after diamond and boron carbide with crisp and sharp performance and certain degree of conductive heat.

silicon carbide for abrasives Application

For abrasives, grinding electronics, metallurgical additive.

For special ceramics, foam ceramics.

For auto parts, war industry and aviation, steelmaking.

For abrasives and cutting tools and cutting disks made of SiC.

For grinding, honing, water-jet cutting and sandblasting.

For lapping and polishing ,metallurgical additive and refractory material.

silicon carbide for abrasives Specification

silicon carbide for abrasives chemical composition | ||

SiC | F.C | Fe2O3 |

≥98.5 | 0.2%max | 0.2%max |

Reviews

There are no reviews yet.