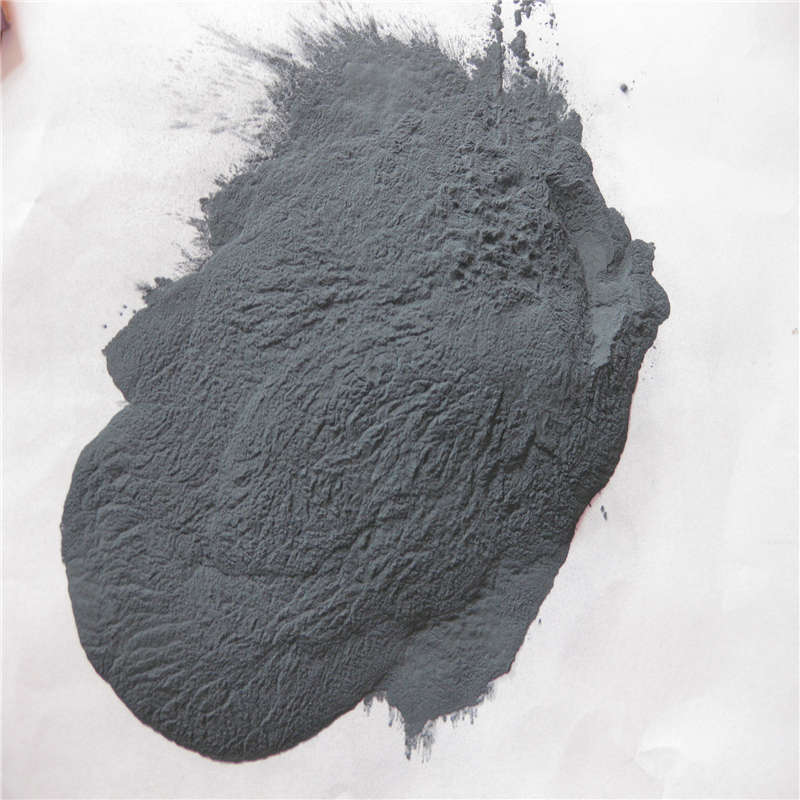

Black Silicon Carbide 360# 400# 600#

Black silicon carbide is produced at high temperature in an electric resistance type furnace with quartz sand, petroleum coke and bits of wood as its main raw materials. Its hardness is between fused alumina and diamond. Mechanical intensity of it is higher than fused alumina. It is crisp,sharp and have certain degree of conductive heat.Black silicon carbide is higher toughness than green silicon carbide with sic purity 98%,it has been used for processing low tensile strength of material, such as glass, ceramics, stone, refractory materials, cast iron and nonferrous metal, etc.Green silicon carbide can also be used in refractories and electronic semiconductor industry.

SiC | 98.5%-99.5% |

Fe2O3 | 0.05-0.1% |

F.C | 0.1-0.2% |

“P” | P240 P280 P320 P360 P400 P500 P600 P800 P1000 P1200 P1500 P2000 P2500 P3000 |

“JIS” | 240# 280# 320# 360# 400# 500# 600# 700# 800# 1000# 1200# 1500# 2000# 3000# |

can be customized according to customer requirements | |

(1)having sharp knife-edge

(2)electrical conductivity, thermal conductivity

(3)high working efficiency

(4)Highly friable abrasive media which is reusable but less durable than brown aluminum oxide

(1)Used as good metallurgical deoxidizer and refractory materials.

(2)Coated the inner wall of water wheel, impeller, cylinder to provide abrasion resistance and prolong life.

(3)Structure of the inferior smooth surface treatment, spraying sand blasting

(4)Grinding and polishing

(5)Ceramics

(6)LED

Reviews

There are no reviews yet.