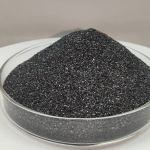

Green silicon carbide for polishing ceramic boilers

Using green silicon carbide (SiC) for polishing ceramic boilers is a very specific and effective application, leveraging the unique properties of this abrasive. Here’s a detailed breakdown of why it’s suitable, how it’s used, and important considerations. Overview: The Goal of Polishing a Ceramic Boiler The primary reasons for polishing the ceramic surfaces inside a