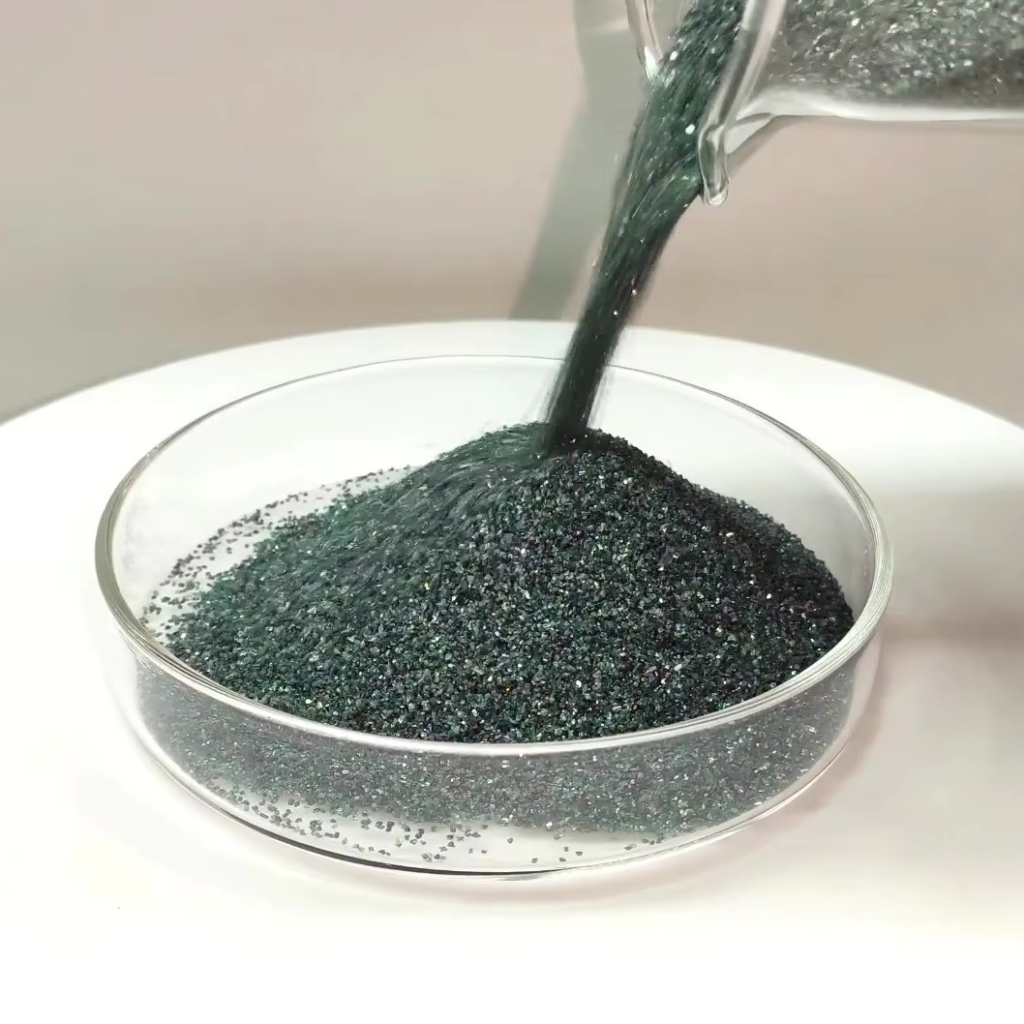

Green Silicon Carbide for Sandblasting Aluminum Alloy Panels

Green silicon carbide (SiC) is a widely used abrasive material for sandblasting aluminum alloy panels, thanks to its high hardness, sharp edges, and good chemical stability. Below is a detailed analysis of its application characteristics, advantages, operating precautions, and alternatives.

1. Core Advantages of Green Silicon Carbide for Aluminum Alloy Sandblasting

(1) High Hardness & Efficient Surface Treatment

Green silicon carbide has a Mohs hardness of 9.2 (second only to diamond and cubic boron nitride), much higher than the hardness of aluminum alloys (generally 2–3 on the Mohs scale). Its sharp, angular particle shape can quickly remove oxide films, surface contaminants, and burrs on aluminum alloy panels without causing excessive deformation of the substrate.It is especially suitable for pre-treatment before coating/anodizing—the rough surface formed after sandblasting can significantly improve the adhesion of coatings or anodized layers.

(2) Chemical Inertness & No Contamination Risk

Green silicon carbide is chemically stable and does not react with aluminum alloys or ambient moisture. Unlike some iron-based abrasives (e.g., steel grit), it will not leave rusty residues on the aluminum surface, avoiding subsequent corrosion problems of the aluminum alloy.

(3) Controllable Surface Roughness

By selecting different particle sizes of green silicon carbide abrasives, you can obtain the required surface roughness (Ra value) of the aluminum alloy panel:

- Coarse particles (e.g., 16–30 mesh): Used for removing thick oxide scales or achieving a coarse matte effect.

- Fine particles (e.g., 60–120 mesh): Used for fine surface finishing, obtaining a uniform and delicate matte texture.

(4) Reusable & Cost-Effective

The high wear resistance of green silicon carbide allows the abrasive to be recycled multiple times in closed-circuit sandblasting systems, reducing the overall abrasive consumption cost compared to disposable abrasives like glass beads.

2. Key Operating Precautions

(1) Control Sandblasting Parameters to Avoid Substrate Damage

Aluminum alloys are relatively soft, so excessive sandblasting pressure or prolonged treatment can cause surface pitting or work hardening. Recommended parameters:

- Air pressure: 0.2–0.4 MPa (adjust according to the desired roughness; lower pressure is preferred for thin aluminum panels).

- Nozzle distance: 10–20 cm (too close will cause local over-erosion; too far will reduce efficiency).

- Sandblasting angle: 45°–60° to the panel surface.

(2) Abrasive Particle Size Selection

| Application Scenario | Recommended Particle Size | Surface Effect |

|---|---|---|

| Oxide film/burr removal | 16–46 mesh | Coarse matte, high cleaning efficiency |

| Pre-treatment for coating/anodizing | 60–100 mesh | Moderate roughness, strong coating adhesion |

| Fine decorative surface | 120–240 mesh | Delicate uniform matte |

(3) Post-Sandblasting Cleaning

After sandblasting, residual silicon carbide dust on the aluminum panel surface must be thoroughly cleaned (using compressed air blowing + ultrasonic cleaning or water washing), otherwise the dust will affect the quality of subsequent processes (e.g., coating peeling, anodizing color unevenness).

(4) Safety Protection

Green silicon carbide dust is irritating to the respiratory tract and eyes. Operators must wear dust masks, goggles, and protective clothing. At the same time, the sandblasting site should be equipped with effective dust removal equipment to avoid dust pollution.

3. Comparison with Common Alternatives

| Abrasive Type | Advantages | Disadvantages | Suitable Scenario |

|---|---|---|---|

| Green Silicon Carbide | High efficiency, no contamination, reusable | Higher cost than glass beads | Pre-treatment for high-quality coating/anodizing, precision surface finishing |

| Glass Beads | Low cost, soft, no surface damage | Low efficiency, cannot remove thick oxide films | Decorative matte surface (no need for strong adhesion) |

| Aluminum Oxide | Moderate hardness, good cost performance | Slightly lower sharpness than SiC | General industrial aluminum alloy cleaning |

4. Application Scope

Green silicon carbide sandblasting is widely used in aluminum alloy products such as automotive parts, aerospace components, electronic enclosure panels, architectural decorative aluminum plates, especially for products with high requirements for surface treatment quality and coating durability.