Green Silicon Carbide for Flexible Abrasive Blocks

Green Silicon Carbide is one of the most commonly used and ideal abrasives for making flexible abrasive blocks (also known as flexible grinding discs, flap discs, or quick-change abrasive discs).

Why Choose Green Silicon Carbide?

Green Silicon Carbide has the following properties that make it ideal for flexible abrasive blocks:

1. High Hardness: Its Mohs hardness of 9.2-9.3 is second only to diamond and boron carbide, making it highly effective in cutting hard materials.

2. Sharp Edges: Green Silicon Carbide crystals have sharp, shattering edges that continuously break under pressure, revealing a new, sharp edge. This creates a self-sharpening effect, maintains stable cutting forces, and resists dulling.

3. Good Thermal Stability: It maintains excellent performance even under the high temperatures generated by grinding.

4. Adequate Toughness: While maintaining sharpness, it also possesses sufficient strength to withstand the pressures of grinding.

Structure of a Flexible Abrasive Block

A typical flexible abrasive block consists of three parts:

1. Abrasive Layer: Made from a mixture of green silicon carbide micropowder and a resin binder. This is the core component that performs the grinding function.

2. Matrix: Typically a high-strength nylon mesh or fiberglass mesh. It provides structural support and excellent flexibility, allowing the block to conform to complex curved surfaces.

3. Adhesive Backing: The back of the abrasive block has a pressure-sensitive adhesive (PSA) that allows for quick attachment to a backing pad, enabling quick replacement.

Applications of Green Silicon Carbide

Molding: Formed into fan-shaped blades through a mold.

Curing: Baking in a high-temperature oven to fully cure the resin and firmly bond the abrasive to the substrate.

Slitting and Assembly: Slicing large sheets into individual fan-shaped blades, assembling them into rings, and applying adhesive.

Main Applications

Due to their excellent performance, green silicon carbide elastic abrasive blocks are widely used for fine grinding, polishing, and finishing of the following materials:

•

Stainless steel weld seam treatment: Removing weld spot and polishing welds are its primary and most important applications.

•

Metal surface treatment: Used for deburring, cleaning, and matte finishing of metals such as carbon steel, alloy steel, aluminum, and copper.

Woodworking: Suitable for fine grinding of hardwood.

Edge finishing of glass, stone, and ceramics.

Automotive: Used for repairing and polishing body sheet metal.

How to choose the right green silicon carbide elastic abrasive block?

The following parameters are key considerations when selecting a grinding tool:

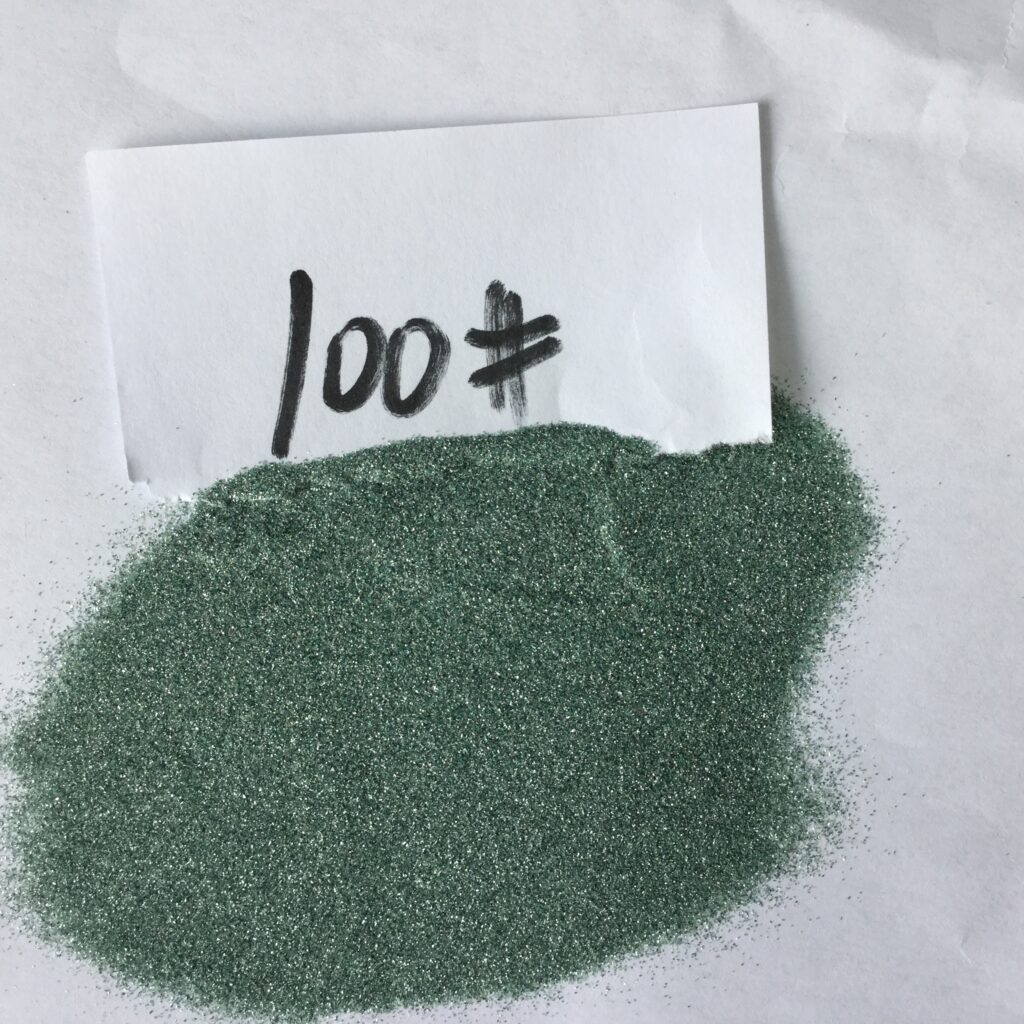

1. Grit:

Coarse grit (e.g., 40#, 60#, 80#): Used for rapid material removal, grinding weld scars, and severe rust.

Medium grit (e.g., 120#, 180#): Used for general grinding and deburring, in preparation for fine grinding.

Fine grit (e.g., 240#, 320#, and even higher): Used for fine grinding, achieving a smooth surface and matte finish.