Green silicon carbide for ceramic boilers?

The following is a detailed analysis of the application of green silicon carbide in ceramic boiler polishing:

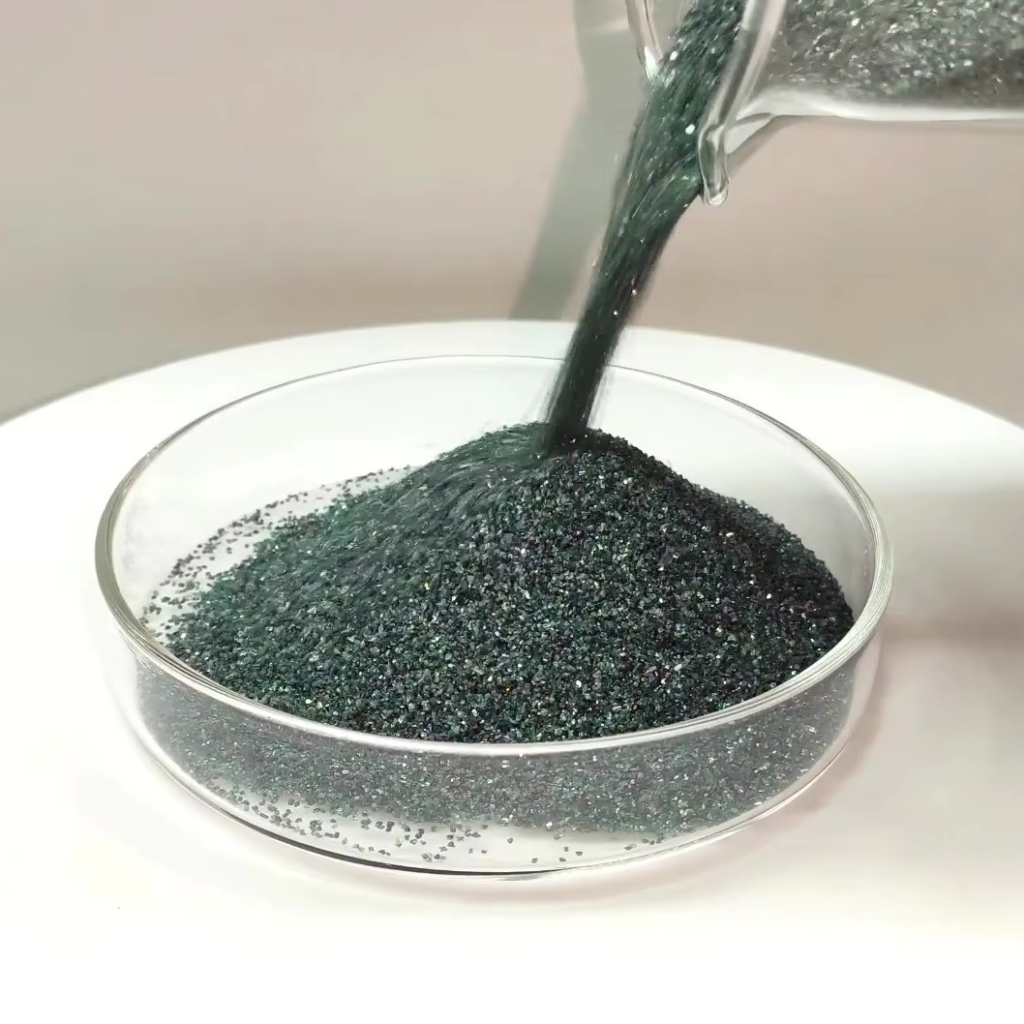

1、 Characteristics of Green Silicon Carbide

High hardness: Green silicon carbide has a relatively high hardness, second only to diamond, with a Mohs hardness of up to 9.4 or 9.5. This characteristic enables green silicon carbide to quickly and effectively remove material from the surface of ceramic boilers during the polishing process.

Wear resistance: Green silicon carbide has excellent wear resistance,

Thermal and chemical stability: During the polishing process, due to the high heat generated by friction and cutting, green silicon carbide can resist the effects of high temperatures, maintaining its hardness and wear resistance.

Uniform particle size distribution: The particle size distribution of green silicon carbide abrasive is concentrated and uniform, and the shape of the abrasive particles is evenly distributed with sharp edges.

2、 Application of Green Silicon Carbide in Ceramic Boiler Polishing

Removing Defects: Green silicon carbide micro powder can uniformly and finely remove small defects and scratches on the surface of ceramic boilers during polishing, making the surface smoother.

Improving glossiness: Through the polishing effect of green silicon carbide, the surface of ceramic boilers can present a brighter luster, enhancing the overall texture of the product.

Maintain consistency: During the polishing process of ceramic boilers, green silicon carbide abrasive can maintain a stable polishing effect, ensuring the consistency of polishing quality.