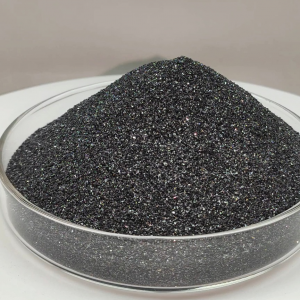

Characteristics and application of 80# black silicon carbide for quartz cutting

Basic product information

Main ingredients: 98.5% SiC.

Physical properties: Mohs hardness is 9.2, second only to diamond and boron carbide, black opaque hexagonal crystals, brittle and sharp, with certain conductivity, and a density of about 3.2g/cm³.

Grit size specification: 80# (F80#) belongs to the commonly used abrasive particle size, corresponding to FEPA standard F80, suitable for medium-precision cutting and grinding.

Quartz cutting suitability analysis

Hardness matching: Quartz Mohs hardness is 7, and black silicon carbide hardness (9.2) is significantly higher than quartz, which can effectively achieve cutting processing.

Performance advantages:

High cutting efficiency: Black silicon carbide has higher toughness than green silicon carbide, and the particles are moderately sharp, which is suitable for processing non-metallic materials with low tensile strength (such as quartz).

Chemical stability: Anti-oxidation at high temperatures, stable chemical properties, avoid chemical reactions with quartz during cutting.

Process parameter reference:

Grit selection: 80# grit (about 180-200μm) is suitable for rough cutting of quartz. If higher precision is required, fine grit (such as 220#, 240#) can be used for subsequent grinding.