The role of green silicon carbide 60# in brake pads?

1. What is Green Silicon Carbide 60#?

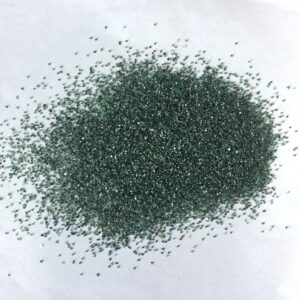

Green Silicon Carbide (GC): An artificially produced mineral known for its extreme hardness (9.5 on the Mohs scale, second only to diamond and boron carbide) and sharp, brittle crystalline structure. Its green color distinguishes it from the more common black silicon carbide. 60# (60 Grit): This refers to the particle size. The “#” stands for “mesh,” which is a measure of grit coarseness. 60# is a relatively coarse grit, with an average particle size of about 250 microns. A lower mesh number means a larger, coarser particle.