Which one is harder, green silicon carbide or black silicon carbide?

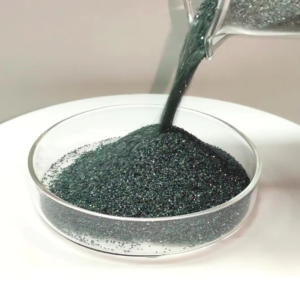

Silicon carbide has two commonly used basic abrasive products: black silicon carbide and green silicon carbide.

1. Black silicon carbide contains about 98.5% SiC, and its toughness is higher than that of green silicon carbide. It is mostly used to process materials with low tensile strength, such as glass, ceramics, stone, refractory materials, cast iron and non-ferrous metals.

2. Green silicon carbide contains more than 99.% SiC and has good self-sharpening properties. It is mostly used to process cemented carbide, titanium alloy and optical glass. It is also used for honing cylinder liners and fine grinding of high-speed steel tools.

Overall analysis shows that the hardness of green silicon carbide is greater than that of black silicon carbide.Because of its stable chemical properties, high thermal conductivity, small thermal expansion coefficient and good wear resistance, black silicon carbide has many other uses besides being used as abrasives, such as being often used as a grinding wheel. The quality of black silicon carbide grinding wheels is mainly determined by the quality of black silicon carbide materials. Grinding wheels produced by high-quality black silicon carbide will also be relatively superior in performance.