Silicon carbide is composed of light elements, silicon (Si) and carbon (C). Its basic building block is a crystal of four carbon atoms forming a tetrahedron, covalently bonded to a single silicon atom at the center. So silicon carbide has a High hardness, Mohs hardness rating of 9, making it the hardest available material next to boron carbide (9.5) and diamond (10). This apparent property makes SiC an excellent material choice for mechanical seals, bearings, and cutting tools, especially the grinding wheel.

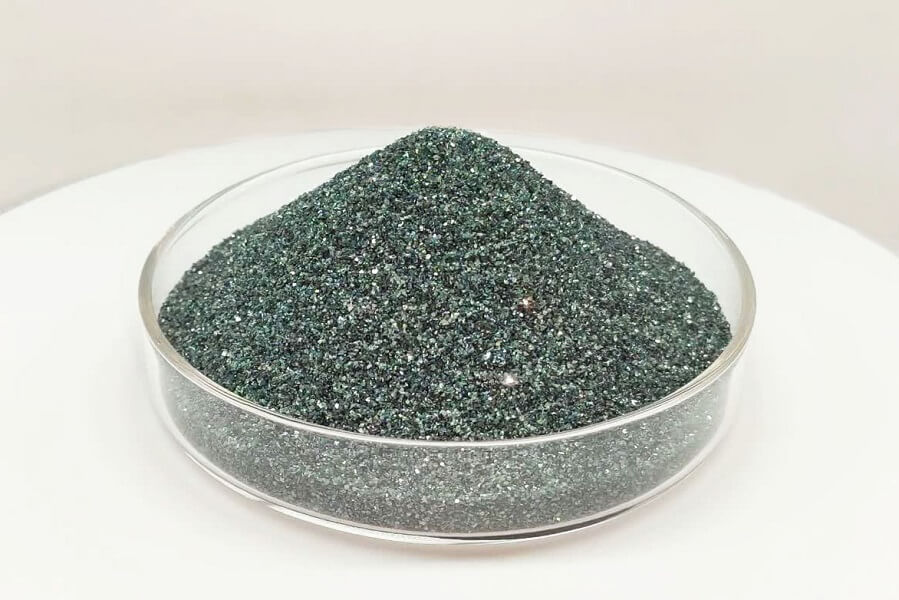

Characteristic of Green Silicon Carbide for Grinding Wheel:

- High hardness

- High wear resistance

- Brittle feature

- High strength, high-temperature resistance

- High-temperature strength

- Low thermal expansion, oxidation

- resistance

- Excellent chemical resistance

- High thermal shock resistance

Technical Data Sheet of Green Silicon Carbide for Grinding Wheel:

| TYPICAL CHEMICAL ANALYSIS | |

| SiC | 99.05% |

| SiO2 | 0.20% |

| F,Si | 0.03% |

| Fe2O3 | 0.10% |

| F.C | 0.04% |

| TYPICAL PHYSICAL PROPERTIES | |

| Hardness: | Mohs:9.4 |

| Specific Gravity: | 3.2g/cm3 |

| Bulk density(LPD): | 1.2-1.6 g/cm3 |

| Color: | Green |

| Particle shape: | Hexagonal |

| Melting Point: | Dissociated at about 2600 ℃ |

| Maximum service temperature: | 1900℃ |

| Friability | Friable |

Applications of Green Silicon Carbide for Grinding Wheel:

| GC grinding wheel for Stone | F46,F60,F80,F120,F150,F180,F220 |

| Cutting disc for marble/Glass/graphite | F36,F46 |

| Bonded Grinding Wheel | F46,F60,F80,F120,F150,F180,F220 |

| Polishing wheel, Sanding disc | F80,F120,F150,F180,F220,F240,F320,F360 |

| F400,F500,F600,F800,F1000,F1200 | |

| Honing stone, whetstone | F800,F1000,F1200,F1500,F2000 |

| Diamond sanding disc | F500,F600,F800,F1000,F1200,F1500 |