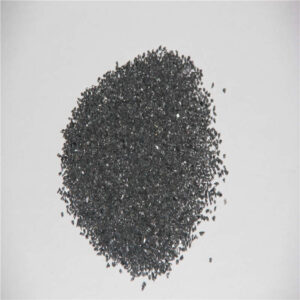

Black silicium carbide 0.5-1mm

Black silicium carbide is made in an electric-resistance type furnace through fusing quartz sand and

petroleum coke with high temperature. Its hardness is between fused alumina and diamond. It has higher mechanical intensity than fused alumina.Black silicon carbide micro powder for metallurgy is acid pickled and syphoned to make sure less residual impurity.

Product feature

* low density

* low thermal expansion, oxidation resistance

* excellent chemical resistance

* high thermal shock resistance

* high wear and hardness resistance

| TYPICAL CHEMICAL ANALYSIS | TYPICAL PHISICAL PROPERTIES | ||

| SiC | ≥97% | Hardness: | Mohs:9.15 |

| SiO2 | ≤1% | Melting Point: | Sublimes at 2250 ℃ |

| H2O3 | ≤0.5% | Maximum service temperature: | 1900℃ |

| Fe2O3 | ≤0.3% | Specific Gravity: | 3.2-3.45 g/cm3 |

| F.C | ≤0.3% | Bulk density(LPD): | 1.2-1.6 g/cm3 |

| Magnetic content | ≤0.02% | Color: | Black |

| Particle shape: | Hexagonal | ||

| AVAILABLE SIZES | |||

| 0-1mm,1-3mm,3-5mm,5-8mm,320-0#,200-0#,325# | |||

Other Specifications with less black silicium carbide

| Item | SiC | F.C | Fe2O3 | Moisture |

| SiC86 | min 86% | max 2.4% | max 2.0% | max 0.2% |

| SiC88 | min 88% | max 2.3% | max 2.0% | max 0.2% |

| SiC90 | min 90% | max 2.0% | max 1.8% | max 0.2% |

| SiC92 | min 92% | max 1.8% | max 1.7% | max 0.2% |

| SiC93 | min 93% | max 1.8% | max 1.6% | max 0.2% |

| SiC95 | min 95% | max 1.0% | max 1.3% | max 0.2% |

| SiC97 | min 97% | max 0.8% | max 1.2% | max 0.2% |

| SiC97.5 | min 97.5% | max 0.8% | max 0.9% | max 0.2% |

| SiC98 | min 98% | max 0.5% | max 0.5% | max 0.2% |