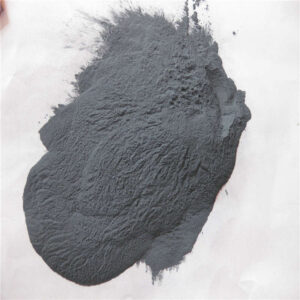

Silicon carbide grit 24 and grit 30

black silicon carbide uses petroleum coke and the high quality silica as the main raw material, via high temperature electric resistance furnace smelting,

Green silicon carbide uses petroleum coke and the high quality silica as the main raw material, adding salt as additive, via high temperature electric resistance furnace smelting, the smelting into crystals of high purity, high hardness, its hardness is between fused alumina and diamond, and mechanical strength is higher than fused alumina.

Silicon carbide is suitable for processing hard alloy, glass, ceramic and non-metallic materials, are also used in the

semiconductor material, high temperature silicon carbide heating element, far infrared source base material, etc.

One of the toughest and most aggressive products in the synthetic mineral ranges for use in a myriad of applications from general blasting and surface finishing of non-aero components, anti slip flooring, vibratory finishing medias, safe manufacture, coated & bonded abrasives and polishing compounds.

Noted for its high thermal stability and wear properties this material is used extensively in refractories, bonded and coated abrasives and precision surface finishing as well as extensively in the safety flooring sector.

Silicon carbide grit 24 and grit 30 applications main properties

Product Name | Black sic grain |

Material | quarts sand and petroleum coke |

color | Black |

standard | FEPA JIS |

Grade | A |

Sic | 98.6%min |

Fe2O3 | 0.20%max |

F.C | 0.15%max |

Maximum service temperature | 1900℃ |

Mohs Hardness | 9.3 |

Specific Gravity | 3.90g/cm3 |

Melting Point | 2250℃ |

Silicon carbide grit 24 and grit 30 applications

• Aerospace Castings

• Anti Slip Floors / Safety Flooring

• Anti Slip Resins and Paints

• Bonded and Coated Abrasives

• Castings and Forgings

• Diffused and Plasma Coatings

• Electronic and Semi Conductor Industry

• Lapping and Polishing/Lapidary/Optical

• Metals: Aerospace approval

• Metals: Cleaning without dimensional change

• Metals: Flash removal

• Metals: Keying surfaces for rubber/plastic bonding

• Metals: Light deburring

• Metals: Peening

• Metals: Removal of hard deposits/investment

• Metals: Matt or textured finish

• Metals: Mould die and tool cleaning

• Metals: Preconditioning and cleaning

• Metals: Preparation for paint metal or plastic spraying

• Metals: Preparation for enamelling/electroplating/anodising

• Metals: Removal of paint/scale/rust

• Metals: Removal of solder/weld/flex

• Metals: Sheen finishing or anti-reflective treatment

• Polishing

• Refractories and Furnace Linings

• Surface Finishing

• Surface Preparation